Joshua Gabriel Paulin (J. G. Paulin) was a Swedish engineer and the inventor of the so-called Paulin System. Paulin was born in Sweden and worked in the cities of Eskilstuna and Stockholm. He developed a precision aneroid barometer of a new type with an adjustable elastic capsule, adapted for accurate altitude measurement (altimetry). For this invention, Paulin received international recognition: in 1932, he was awarded the Longstreth Medal by the Franklin Institute (USA). In Sweden, he founded the company System Paulin AB (Paulin System Joint Stock Company, Stockholm) to manufacture his instruments.

H. E. Linden was an American engineer who played a key role in the introduction of the Paulin System to the United States. He became acquainted with Paulin’s invention and initiated local production. In the late 1920s, Linden founded American Paulin System, Inc. in Los Angeles, having obtained a license for Paulin’s technology. Linden established cooperation with the Swedish inventor and adapted the design for the American market. Although little is known about Linden’s biography, it is clear that he headed the initial manufacturing projects in California and actively promoted Paulin instruments in the U.S. By 1929, the American company had established a dealer network: the journal Aviation reported on H. L. Balderston, a former employee of American Paulin System, Inc., who moved on to a position at Pioneer Instrument Co. This indicates that by the end of the 1920s, the firm was an active player in the aviation and navigation instrument market.

Company Foundation and Development Stages

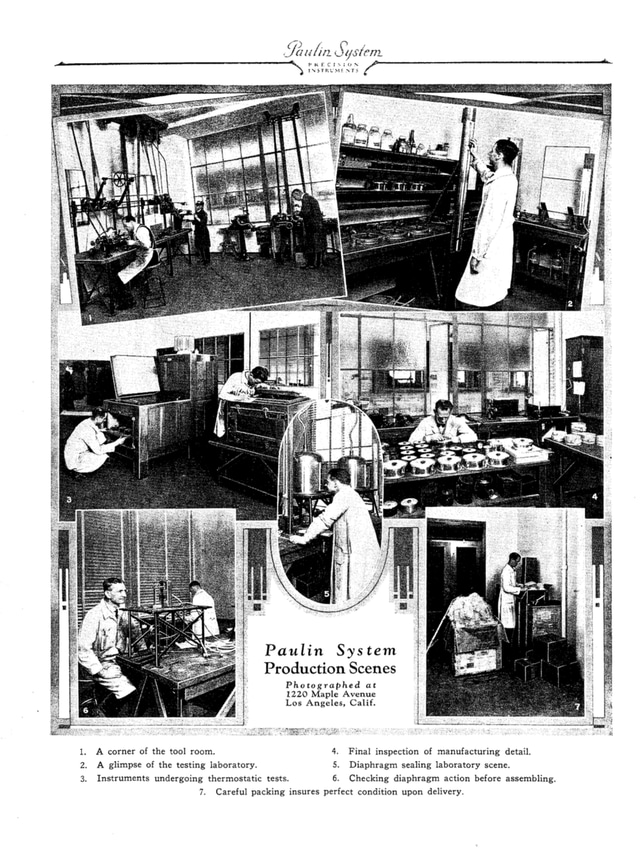

The first production using the Paulin System was set up in Sweden (Eskilstuna). Around 1927, American Paulin System, Inc. announced the opening of a plant in California. Business press from San Francisco in early 1927 noted that American Paulin System, Inc. was launching a new production line for altitude meters. The headquarters was located at 1220 Maple Avenue, Los Angeles, California—this marking appears on one of the company’s early instruments. In 1929, the company published an illustrated catalog titled Paulin System Precision Instruments, offering barometers and altimeters based on its proprietary technology. One of the top products of 1929 was an altimeter model called “The Engineer”, priced at $125.

In its early years, the company experienced a surge due to the uniqueness of the system. However, the economic hardships of the Great Depression affected it as well. In September 1930, a reorganization was announced: the production operations of American Paulin System, Inc. (Los Angeles) were relocated to Meriden, Connecticut. This likely signaled either a merger with an East Coast partner or an attempt to cut costs by moving closer to industrial centers of instrumentation. Nevertheless, by the mid-1930s, the headquarters was again listed in California. In 1935 archives, the company is identified as a manufacturer of precision instruments in Los Angeles. By the 1940s and 1950s, the company’s address was listed as 1847 South Flower Street, Los Angeles 15, CA, and its product range expanded. Trade journals from the 1950s mention not only altimeters but also devices such as regulated power supplies. This points to diversification: in addition to altimeters for surveying, the firm attempted to offer electronic power units and other measuring devices.

In the 1960s–70s, American Paulin System continued producing small series of altimeters. Structurally, they remained true to the “Paulin System”—high-precision aneroid gauges with zero-setting mechanics. However, the mass market for pressure instruments was increasingly dominated by electronic and cheaper alternatives. The output of Paulin devices steadily declined.

By the 1980s–90s, the company had significantly scaled down. Around 1997, American Paulin System moved its operations from California to Arizona. Its last known address was in Cottonwood, AZ (Yavapai County). There, the firm was classified under “Surveying Instruments” and likely engaged in servicing or selling remaining stock. During this period, the company was led by engineer Lyle Jacobsen, listed in business records as president of American Paulin System, residing in Cottonwood. It is likely that he tried to preserve the company’s legacy for a small circle of users. Eventually, however, the company ceased operations. Barometric instrument enthusiasts note that the company effectively closed by the late 1990s. In modern industry, there is no direct successor; the Paulin System survives only in museum pieces and private collections.

It is worth noting that Paulin System instruments today represent a valuable part of measurement technology history. For instance, one of the firm’s altimeters, used by Charles Lindbergh and his wife during their 1933 transatlantic flight aboard the Lockheed Sirius Tingmissartoq, is now on display at the National Air and Space Museum (Washington, DC). This model, installed aboard the legendary Lindbergh aircraft, testifies to the fact that at the time, the Paulin System was considered one of the most sensitive altimeters in aviation.

Patents and Technical Solutions of the Paulin System

The inventions of J. G. Paulin were protected by patents in multiple countries. The key patents for the Paulin System were granted in the United States:

Paulin also patented several other improvements—for instance, US 1,980,732 (1934) describing refinements in the pointer suspension with a compensating element, and US 2,302,713 (1942), which involved a flow-speed meter that accounted for both airspeed and static pressure, likely aimed at aircraft. These patents extended the applicability of the Paulin System (e.g., to airspeed indicators) and demonstrated its versatility. Nevertheless, the core of all technical innovations remained the principle of pressure balancing through an adjustable spring.

Operating Principle of the Paulin Measuring System

The Paulin System is a refined aneroid-type measuring instrument that operates based on a balanced comparison method. In a classical aneroid barometer, changes in atmospheric pressure cause an elastic metal capsule to flex, and this tiny movement is transmitted through a gear to a needle. Paulin’s approach differs: two vacuum-sealed capsules are arranged in series for increased sensitivity, and they are opposed by a spiral spring trying to separate them.

The needle does not directly display pressure; instead, it functions as an equilibrium indicator. The user rotates an external adjustment knob, changing the tension of the spring. When the spring force exactly balances the ambient pressure, the needle returns to its central (zero) position. The value of the pressure (or corresponding measured quantity) is then read from a separate graduated scale linked to the screw mechanism. In simple terms, the system works via a “zero-balance” method: the operator “tunes” the system to equilibrium and obtains the result by noting the setting of the adjustment screw.

This method offers several advantages. First, it enhances accuracy—even small pressure changes are noticeable because the user can balance the system with great precision, and the scale on the adjustment screw is finely graduated (early Paulin instruments even used mirror scales to eliminate parallax). Second, it eliminates many mechanical inaccuracies: the motion transmission system works with virtually no friction, avoiding the long gear trains in regular aneroids that often “absorb” movement. Paulin emphasized in his patents that his design eliminated variable capsule resistance—pressure is always balanced by the spring near the center position, where the capsule is most linear. Third, it expands the measurement range. The spring balancer can be preset for different ranges: by adjusting its pre-tension, the user could measure both small and large altitude differences—just by turning the screw further. The 1929 catalog stated that the same device could function as both a barometer and an altimeter for elevations up to several thousand meters—with appropriate tables and calibrations.

Paulin System instruments had a characteristic appearance: a rectangular metal case, a large circular dial, and an auxiliary window with a secondary pointer or marker. The measurement process was as follows: the observer turned the adjustment knob until the pointer returned to zero (or a marker aligned in a mirror or window), indicating internal balance. Then, the main scale was read—yielding, for instance, altitude above sea level. To account for temperature and daily pressure fluctuations during barometric leveling, correction tables were provided (American Paulin System issued user manuals for altimetric leveling and meteorological corrections). Some models included built-in thermometers and leveling bubbles for comprehensive environmental control.

Applications of Paulin System Instruments

Paulin’s aneroid altimeters were primarily used in geodesy, geology, and mining. In the late 1920s and 1930s—before portable electronic altimeters became available—Paulin System devices were widely employed for barometric leveling of terrain. For example, in 1929, American Paulin System published a manual on using altimeters in topographic surveys, describing techniques for determining point elevations based on atmospheric pressure differences. In geological practice, such altimeters were used for the preliminary assessment of rock elevations, route planning, and similar tasks. They allowed for relatively quick (though approximate) altitude measurements in remote areas without the need for bulky leveling equipment. Reports from the 1940s mention the use of Paulin altimeters by geological services: in 1946, the Mississippi Geological Survey combined benchmark data with measurements taken using an American Paulin altimeter when producing maps. The main advantage was mobility—the instrument fit into a small case and required no power source.

In industry, Paulin instruments served as precision barometers. Mining companies purchased them for assessing the height of tunnels and shafts based on air pressure, and construction firms used them as well. The 1929 catalog advertised models for engineers and mine surveyors, emphasizing their reliability and accuracy when properly calibrated. Some models were given marketing names—for instance, “The Engineer” was intended for civil engineers, while the “Surveyor’s Altimeter” targeted professional surveyors. There were also microbarometers for scientific laboratories, with extended scales allowing detection of even minute atmospheric pressure variations. Such instruments were used by meteorologists and in aerological research before the advent of electronic sensors.

In aviation, the Paulin System never gained as much traction as the competing Kollsman altimeter, but it did leave a mark. As mentioned earlier, Charles Lindbergh’s Lockheed Sirius was equipped with a sensitive Paulin altimeter during one of his transatlantic flights. Pilots may have appreciated the high precision of the “null method” when calibrating at known altitudes and tracking changes. However, for routine flying, more convenient altimeters with automatic compensation and a single pointer (like the Kollsman altimeter, invented in 1928) proved more practical. As a result, Paulin devices remained a niche solution, often used in aeronautical research—for calibrating barographs or during aerial mapping where exact height recording was needed.

In science, Paulin instruments are mentioned in connection with expeditions and measurement complexes. Museums hold examples used by researchers (in addition to Lindbergh, other explorers likely carried such barometers). Their high accuracy and autonomy made them valuable before the rise of digital barometers. For instance, one Paulin Aneroid Altimeter from the Smithsonian Institution’s collection is displayed with its original manual and correction tables.

Today, Paulin System Instruments are considered rarities. They are highly valued by collectors of aneroid barometers and historians of science. Their construction laid the groundwork for the concept of the compensated aneroid, which later influenced a range of scientific devices. Although the manufacturing company no longer exists, the legacy of J. G. Paulin lives on in museums and textbooks as a striking example of engineering ingenuity—enhancing the accuracy of measuring a natural quantity (atmospheric pressure) through purely mechanical means.